Hello All,

We’re happy to announce a couple of new features across the Pollination ecosystem, which are complementary to one another.

Appendix G Performance Recipe

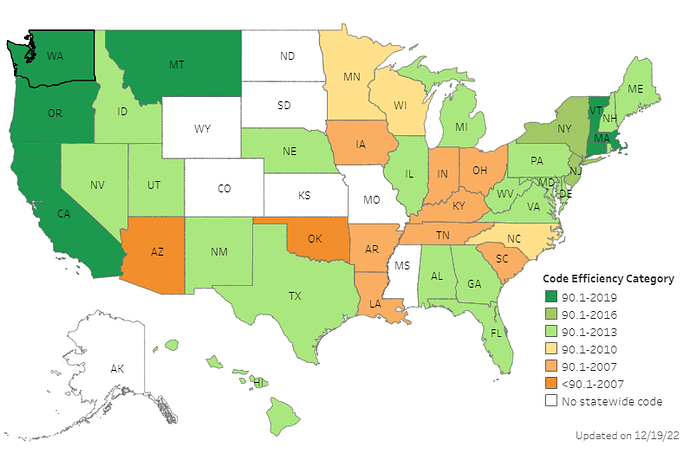

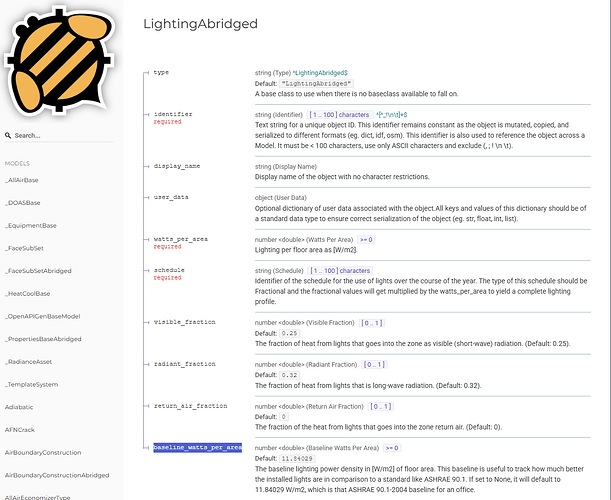

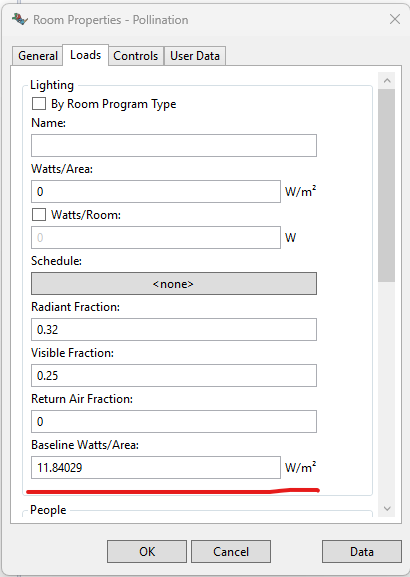

After many of you have asked us for it, we have finally published a recipe to Pollination that can estimate the number of LEED “Optimize Energy Performance” credits that a particular model can achieve! The recipe is called Appendix G Performance and you can find it here on the Pollination platform or by searching for available recipes with the PO Setup Runs component. Just as the name of the recipe implies, it generates a baseline Model (as a HBJSON) from the input Model, which is consistent with ASHRAE 90.1 Appendix G 2016 (and later). This includes adjusting the geometry, constructions, lighting, HVAC, SHW, and removing any clearly-defined energy conservation measures like daylight controls. The recipe even performs an initial EnergyPlus sizing run on the baseline model to ensure that all HVAC equipment efficiencies align with the 90.1 standard.

After the creation of the baseline model, the recipe executes an annual EnergyPlus simulation, performing 4 separate simulations of the baseline model in parallel for each of the 4 cardinal directions per the Appendix G specification. Alongside these baseline simulations, the input Model is also simulated to get the energy performance of the proposed building. At the end, all energy use results are post-processed along with the energy costs inputs to estimate the Appendix G Performance Cost Index (PCI) for the latest 3 versions of ASHRAE 90.1 (2016, 2019, and 2022). An additional step is run to estimate the number of LEED “Optimize Energy Performance” points for LEED v4 (and 4.1), using inputs of electricity carbon intensity alongside the energy cost inputs.

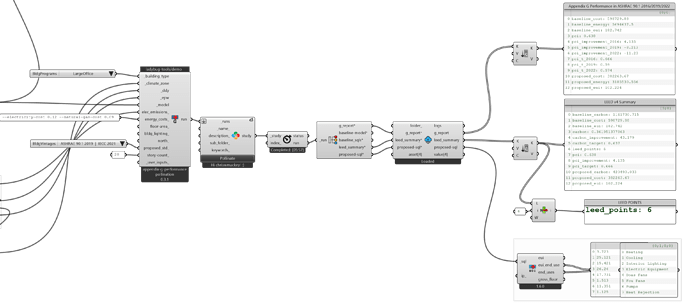

The ultimate output of the recipe is a couple of JSON summaries, which note the Appendix G performance and the LEED Energy performance. The first file is called appendix_g_summary.json and a sample of this is visible below (note the PCI improvement in percent for the latest versions of ASHRAE 90.1):

{

"proposed_eui": 112.866,

"proposed_energy": 3517144.444,

"proposed_cost": 703428.89,

"baseline_eui": 235.3,

"baseline_energy": 7332474.306,

"baseline_cost": 1214797.19,

"pci_t_2016": 0.666,

"pci_t_2019": 0.591,

"pci_t_2022": 0.574,

"pci": 0.579,

"pci_improvement_2016": 13.055,

"pci_improvement_2019": 2.0219,

"pci_improvement_2022": -0.880

}

You will see that it is possible to get “negative improvement”, especially in the later versions of ASHRAE 90.1, where the performance targets are strict. This isn’t always an indication of a poor design since the Appendix G PCI metric is highly susceptible to relative cost differences between energy sources like electricity vs. natural gas. So we recommend that users take care with the energy cost inputs for the recipe and set them to the real values of their project, even though the recipe has reasonable defaults that align with average US prices.

The recipe also outputs a file called leed_summary.json, which contains the

ASHRAE 90.1-2016 PCI for both cost and carbon (GHG) emissions in the format below.

{

"proposed_eui": 112.866,

"proposed_cost": 703428.89,

"proposed_carbon": 464263.067,

"baseline_eui": 235.3,

"baseline_cost": 1214797.19,

"baseline_carbon": 1577657.766,

"pci": 0.579,

"pci_target": 0.666,

"pci_improvement": 13.055,

"carbon": 0.294,

"carbon_target": 0.633,

"carbon_improvement": 53.511,

"leed_points": 9

}

Note the total number of LEED points at the very end is out of the total possible (16, 18, 20) that can be achieved under the “Optimize Energy Performance” category. Altogether, the execution of the recipe looks like this from Grasshopper:

We have provided a Grasshopper sample of a full-building Large Office model (built with Dragonfly) for those who wish to get started testing the recipe. NOTE THAT YOU WILL NEED TO HAVE POLLINATION RHINO 1.25.7 OR ABOVE INSTALLED TO CORRECTLY USE THE RECIPE. You can get this either by downloading and running the latest Pollination Rhino installer or by running the LB Versioner component from Grasshopper. Hopefully, it also goes without saying that the recipe is intended for full-building models that have all of the critical energy simulation properties assigned to them (ConstructionSets, ProgramTypes and detailed HVAC Systems). The recipe won’t fail for cases like a model with ideal air load systems but the results aren’t likely to be meaningful given that an ideal air system is not a real piece of HVAC equipment and it reports all energy usage as district heating/cooling.

All of the methods that the recipe uses are open source and those of you familiar with Appendix G modeling probably already know that we are relying heavily on the OpenStudio Standards gem in order to build the baseline HVAC systems and assign efficiencies to all of the HVAC equipment. So, as is typical with many of our releases, a great deal of thanks is due to the National Renewable Energy Lab and the OpenStudio team. The Ladybug Tools methods that edit the building geometry and assign baseline constructions are also open source and many of them can be found within this new honeybee_energy.baseline subpackage. Lastly, the logic of the recipe itself is open source and is available here under the Pollination Github.

We would like to emphasize again that Appendix G in ASHRAE 90.1 2016 (and later) sets a relatively high standard of energy efficiency and is close to aligning with the AIA’s goal of carbon neutral practices by 2030. When using only the detailed HVAC template systems that are shipped with Ladybug Tools and Pollination Rhino, it can be very difficult to get all available LEED points. For the Large Office sample model provided above, we were not able to get more than 9 LEED points after applying the best energy conservation strategies that we know. It’s likely that, to get all available LEED points, some amount of on-site renewable energy may be necessary for certain buildings. We are working towards a specification of photovoltaic panels in Honeybee that will enable this but, in the meantime, there are likely still a few more LEED points that can be achieved by fine-tuning the efficiency of HVAC equipment and implementing strategies beyond what the template HVAC systems allow. For this reason, we are particularly excited to announce this Appendix G capability alongside a new-and-improved Ironbug integration!

Ironbug Integration with Honeybee Models

Many of you are already familiar with the Ironbug plugin that @mingbopeng has developed and maintains. The plugin provides over 100 components for customizing HVAC systems to a high level of detail, effectively providing the full set of capabilities of the OpenStudio SDK for HVAC. In the past, it was possible to use Ironbug with certain Pollination recipes that could accept the Ironbug-edited OSM file as the input model but other recipes like the comfort mapping and the Appendix G recipe above require a model in Honeybee (HBJSON) format because they pre-process the model with the Ladybug Tools core Python libraries before they simulate them in engines like EnergyPlus/OpenStudio.

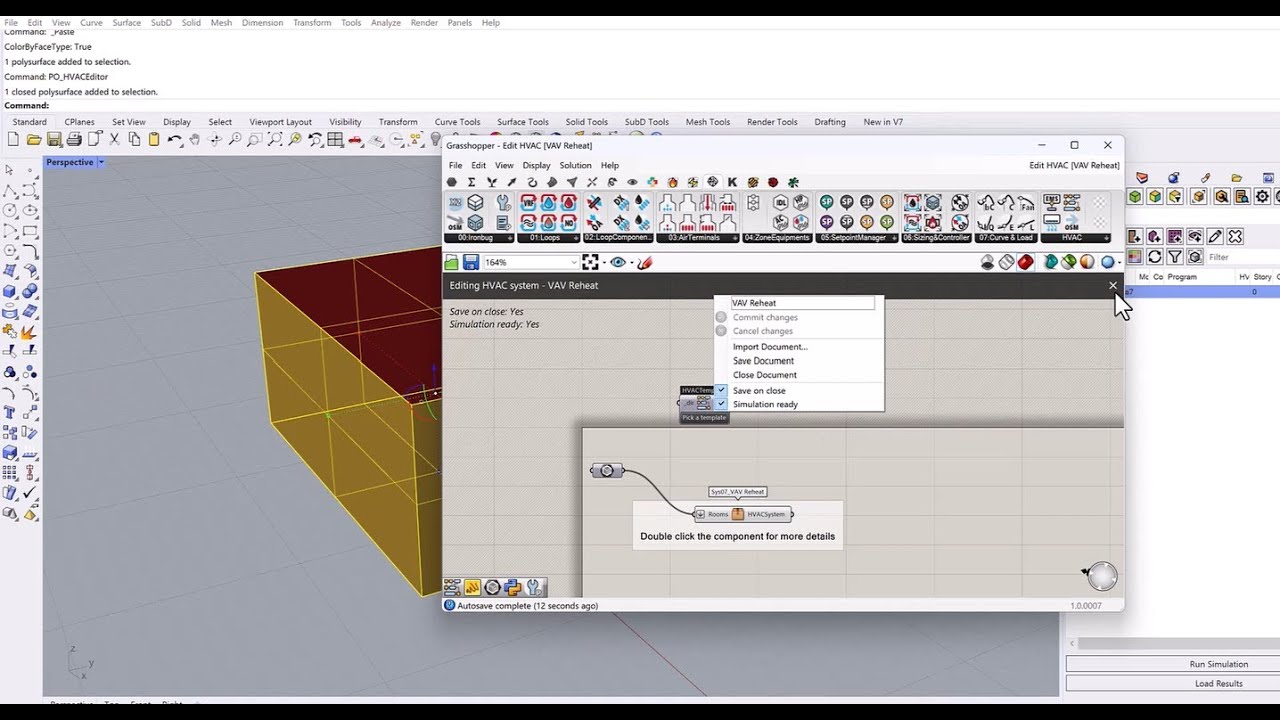

For these reasons, it’s with great pleasure that we announce Ironbug has been fully integrated into the Honeybee Model schema (aka. HBJSON). This means that you can assign your Ironbug HVAC to Honeybee Rooms using a new LBT-Grasshopper component called “HB Detailed HVAC’’ like so:

The resulting Ironbug HVAC will be automatically included in any OpenStudio/EnergyPlus simulation of the Honeybee Model and a full specification of the Ironbug HVAC is included in the Honeybee Model JSON (HBJSON) that gets uploaded to the Pollination platform or any online simulations. This enables you to set efficiencies of HVAC equipment down to a very fine level of detail and model many more energy conservation strategies than the template HVAC systems allow. By modeling things like high-performance chillers/ heat pumps, adding heat recovery strategies like run-around loops, and using thermal resources like ground heat exchangers, many of the LEED credits for the recipe above can be achieved.

This is our first step to provide better solutions for modeling detailed HVAC systems as part of our development roadmap for 2023. In the next few weeks, we will be working towards an even stronger integration between Ironbug and the Pollination Rhino plugin, effectively making Ironbug and Grasshopper the default interface for building and editing detailed HVAC systems for your Pollination Rhino models. The video below provides a sneak preview of what to expect with new HVAC integration and how we’ll be making use of Grasshopper as a dedicated HVAC editor.

So stay tuned and, as always, please feel free to open a new discussion topic on this forum for any questions or feedback on the new capabilities!